If you’re running Texa diagnostic tools, you’re already a step ahead of the curve. Whether you’re servicing heavy-duty trucks, marine engines, agriculture equipment, or powersports vehicles — Texa gives you powerful insight and control over complex systems. But here’s the catch: your Texa subscription is more than just software updates — it’s the key to maintaining your unlimited warranty.

At Defy Diagnostics, we help customers renew their subscriptions every day, and we see what happens when that renewal gets delayed. Let’s break down why staying current with your TEXA subscription is absolutely essential.

What Does a TEXA Subscription Include?

Your TEXA subscription unlocks the full value of your diagnostic investment, including:

- Regular software updates with the latest coverage and OEM-level capabilities

- Unlimited technical support for troubleshooting and guidance

- Warranty protection that lasts indefinitely — as long as your subscription stays active

This isn’t just a software license — it’s peace of mind that your tool will keep evolving with the vehicles you service.

The Danger of Letting Your Subscription Expire

One of the most common issues we see? Shops and technicians accidentally let their subscription lapse — even just for a few months — and lose their unlimited warranty status. Here’s what that means:

- Warranty becomes void. Even if your tool is just a few years old, a gap in your subscription can disqualify it from future warranty service.

- No more updates. Without current software, your diagnostics may miss newer vehicle systems or throw false codes.

- Support access is limited. You’ll lose direct access to technical support teams trained specifically on TEXA.

The Simple Solution: Renew with Defy Diagnostics

Renewing your Texa subscription with Defy Diagnostics is fast and hassle-free. Defy Diagnostics is an authorized Texa partner, and we gaurantee:

- Lowest price on official TEXA subscription renewals

- No hidden fees, ever — what you see is what you pay

- Fast processing and activation

- Expert support from a U.S. based team

Click here to renew your TEXA subscription now.

Even if your subscription has already lapsed, we can help evaluate your options and get you back on track.

Don’t Risk Losing Your Unlimited Warranty

TEXA’s unlimited warranty is a huge value, but it’s only available if you stay subscribed. Missing a renewal could mean the difference between a quick fix and a costly replacement. Protect your investment — and your uptime — by renewing today.

Need Help or Have Questions?

Defy Diagnostics is here to help you every step of the way. Call us, message us, or email for expert help with TEXA subscriptions, renewals, or product support.

Here’s What Code 3712 Means — and How to Fix It Fast

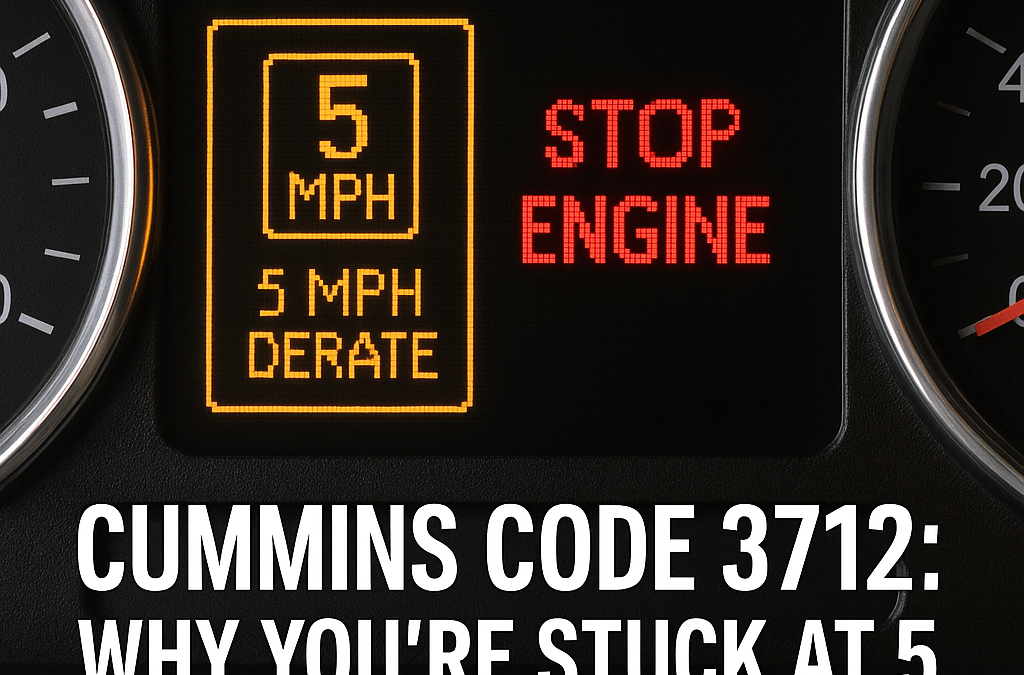

If you’ve ever had a Freightliner Cascadia, Kenworth T680, or Peterbilt 579 crawl into the shop stuck at 5 mph, chances are you’ve seen Cummins Fault Code 3712 staring you in the face. This one isn’t just a random check engine light — it’s an SCR inducement event tied to SPN 5246 FMI 0, and it means the system has had enough. Once this hits, you’re dealing with an emissions-related shutdown designed to force immediate repair.

Whether it’s an ISX15 in a long-haul tractor, a B6.7 in a Blue Bird Vision bus, or a QSX15 in a CAT 390 excavator, this fault code carries the same message: Your aftertreatment system is in critical condition — fix it now, or you’re parked.

Let’s break down what causes it, how to troubleshoot it properly, and why having the right diagnostic gear — like TEXA’s Axone Voice, Multihub 2, or the remote-capable TEXA eTRUCK — can make all the difference when time is money.

What Is Cummins Fault Code 3712?

This fault appears as SPN 5246 FMI 0, officially labeled “Aftertreatment SCR Operator Inducement – Most Severe Level.” It’s not a standalone fault — it’s triggered by other active, critical SCR-related codes. Think of it as the system’s way of saying: you’ve had your warnings, now you’re getting derated.

Which Engines and Vehicles Are Affected?

This fault code impacts a wide range of Cummins engines, including:

- ISX15 / X15 – Freightliner Cascadia, Kenworth T880, Peterbilt 389

- B6.7 / ISB – Blue Bird Vision, Thomas Built buses, delivery vehicles

- ISL9 / ISC8.3 – International MV Series, vocational trucks

- QSX15 – Off-highway equipment like excavators, generators, mining rigs

What Triggers Fault Code 3712?

While the root cause varies, here are the most common culprits:

- Malfunctioning inlet or outlet NOx sensors (especially if they can’t reach operating temp)

- DEF dosing valve or pump failure due to contamination or crystal buildup

- SCR catalyst degradation from long-term exposure or fluid contamination

- Poor DEF quality (outside 31–34% range) or freezing/crystallization issues

- Wiring or ECM calibration issues impacting communication with aftertreatment system

Field Diagnosis: How the Pros Approach It

Step one: confirm that 3712 is paired with one or more actionable SCR-related codes. Then follow this basic workflow using professional-grade diagnostics:

- Scan with TEXA Axone Voice + Multihub 2 — pull active codes, view live data, and confirm calibration

- Inspect NOx sensor temps — 250°F+ for inlet, 450°F+ for outlet

- Visually inspect DEF lines for leaks, crystal deposits, and pressure issues

- Run dosing valve and SCR conversion efficiency tests using TEXA IDC6 software

Need fast regen access and live fault monitoring without rolling a truck? TEXA’s eTRUCK lets you monitor, diagnose, and even perform remote regens — ideal for fleets with Cummins-powered assets on the road.

Repair Procedures and Best Practices

Once you’ve confirmed the cause, here’s what usually comes next:

- Replace faulty NOx sensors and verify calibration

- Service or replace DEF dosing unit and clean tank if needed

- Replace SCR catalyst if efficiency is below threshold

- Flush DEF system and update ECM calibration

Once repairs are complete, use TEXA tools to run SCR efficiency tests, confirm sensor readings, and ensure fault codes clear properly before release.

Preventive Maintenance to Avoid Code 3712

- Test DEF quality monthly and replace fluid regularly

- Keep up with SCR catalyst efficiency testing

- Inspect NOx sensors and wiring every 90 days

- Update ECM calibrations regularly (Cummins typically releases updates every 6–8 weeks)

Stay Ahead of the Next Breakdown

At Defy Diagnostics, we’re here to keep your fleet running and your downtime to a minimum.

Sign up for our free newsletter and get:

- Pro diagnostic tips like this one

- Exclusive offers on TEXA tools and accessories

- Updates on IDC6 software features and releases

- Field-tested repair strategies you can trust

Sign up now and keep your shop one step ahead.

Detect AC Leaks with Confidence: Why the TEXA Forming Gas Kit Belongs in Your Shop

When it comes to A/C system diagnostics, guesswork is not an option. Whether you’re servicing a vehicle after a collision repair or troubleshooting a drop in cooling performance, identifying leaks quickly and precisely is critical — both for customer satisfaction and your bottom line.

That’s where the TEXA Forming Gas Kit with H₂ Detect comes in.

Tackle Micro Leaks Other Tools Miss

Traditional methods like nitrogen pressure testing or UV dye can leave you with more questions than answers:

- Nitrogen alone may show a pressure drop — but not the leak location.

- UV dye requires time, extra flushing, and often doesn’t pinpoint small or fast-dissipating leaks.

With TEXA’s Forming Gas Kit, you inject a 95% nitrogen / 5% hydrogen gas mixture into the system. Then, using the H₂ Detect sniffer, you can zero in on even the tiniest hydrogen molecule escaping — with visual and audible alerts that guide you directly to the leak source.

Hydrogen is the lightest, smallest molecule — making it ideal for tracking micro leaks in systems using R134a, R1234yf, or R744 (CO₂).

Built for Collision Repair & High-Precision A/C Service

If you’re recharging A/C systems without leak verification, you’re playing a risky game. Collision repairs often disrupt seals or lines — and the last thing your shop needs is a comeback. TEXA’s forming gas method:

- Meets Daimler AG requirements

- Is non-polluting and safe to use

- Works across multiple refrigerant types

- Detects even hard-to-find slow leaks before the system is recharged

What’s in the Kit?

Forming Gas Cart TTF 700

- Compatible with R134a, R1234yf, R744

- Max pressure: 100 bar

- Service hoses for all refrigerants

- Safety valve, pressure reducer, manometer

- Secure tank storage (tank not included)

Forming Gas Case

- Adapters, reducer, evacuation valve

- Teflon seals

- Connection kit for Konfort A/C machines

H₂ Detect Sniffer

- Measures hydrogen from 0 to 2000 ppm

- 14-second response time

- Visual and acoustic feedback

- 6-hour battery life

- Flexible probe for hard-to-reach areas

Who’s It For?

Whether you’re a:

- Collision center needing OEM-approved diagnostics

- Independent repair shop handling A/C complaints

- Dealer staying ahead of new refrigerant standards

- Mobile technician chasing down tough leaks

The TEXA Forming Gas Kit gives you the confidence to diagnose accurately — and avoid repeat repairs.

Need Help Getting Started?

Our team is here to help you integrate leak detection into your A/C service process. Need help pairing the kit with your Konfort 760 Touch or 780 Touch? Just ask.

📞 Talk to a Pro at Defy Diagnostics today.

What is ADAS Calibrations?

ADAS calibration involves the precise adjustment and alignment of a vehicle’s Advanced Driver Assistance Systems (ADAS), which include features such as lane departure warnings, adaptive cruise control, collision avoidance, and blind spot detection. For these safety systems to function properly, their cameras, sensors, and radar units must be correctly calibrated according to the vehicle’s specifications.

Calibration is essential whenever these components might have shifted — whether from a collision, windshield replacement, suspension work, or even normal wear and tear. Even slight misalignment can result in inaccurate data, false alerts, or a dangerous failure to detect real threats on the road.

Is ADAS Calibrations right for your business?

As vehicles become increasingly advanced, it’s important to ask: is ADAS calibration a necessary service for your business? The short answer is yes. Accurate calibration is critical to ensuring systems like automatic emergency braking, forward collision warning, and lane-keeping assistance perform safely and reliably.

Why Precision Matters in ADAS Calibration

If you’re thinking about offering ADAS calibration services, understand this: precision is non-negotiable. These systems rely on finely tuned cameras, radar, and sensors to operate correctly. Even a slight misalignment can lead to inaccurate readings, false alerts—or worse, failure to detect real hazards.

Calibration is often needed after events like:

- Collisions (even minor ones)

- Windshield replacement

- Suspension repairs

- Wheel alignments

- Routine wear and tear

That’s why your calibration facility must allow for easy access and precise adjustment of all ADAS components.

Space Requirements: Do You Have Room for ADAS Calibration?

Before you invest in ADAS equipment, assess your available space. A proper calibration environment isn’t just “nice to have”—it’s essential.

General guidelines:

- Minimum space: 30 x 50 feet

- Larger vehicles may need even more room

- The area must be flat, unobstructed, and free from overhead interference

Most collision repair shops struggle with this—an estimated 80% don’t have enough space for proper calibrations. If space is tight, consider renting or expanding your facility.

Key environmental requirements include:

- Level flooring

- Uniform, adjustable lighting

- Power access and equipment storage

- Minimal reflective surfaces and proper ventilation

Lighting Requirements: Avoid Calibration Errors

Lighting plays a major role in calibration accuracy. Poor lighting can cause system errors, misalignment, and failed recalibrations.

What you need:

- High-quality, flicker-free LED lighting

- Uniform, diffused illumination across the workspace

- Adjustable lighting to adapt to seasonal or time-of-day changes

Tips for optimal lighting:

- Avoid direct lighting over windshields or hoods

- Use shades or curtains to block natural glare

- Deploy a light meter to ensure consistent luminance throughout the shop

Flooring Considerations: Keep It Level and Safe

Your floor must be:

- Flat and level (within +/- 10mm, per OEM specs)

- Non-reflective and low-gloss

- Easy to clean and durable

Recommended materials: concrete, epoxy resin, or vinyl.

Power Supply: Stay Powered, Stay Accurate

Reliable power is crucial for running ADAS calibration equipment.

Must-haves:

- Stable, nearby electrical outlets

- Uninterrupted power supply (UPS) to avoid calibration interruptions

- A backup power source (like a generator) if consistent electricity is an issue

Environmental and Facility Factors

Aside from lighting and space, be mindful of other environmental variables that could compromise accuracy:

- Sunlight & Reflections: Block or diffuse direct sunlight and remove reflective surfaces like mirrors, metal posts, and glass doors.

- Ventilation: Proper airflow is essential, especially when working with chemicals or running vehicles.

- Temperature & Humidity: Keep conditions consistent for both the operator and equipment.

- Wall Coating: Use light-colored, non-glossy paint that matches the floor for a distraction-free calibration area.

Internet Access: Stay Connected

A strong internet connection is non-negotiable. You’ll need it for:

- Downloading software updates

- Accessing calibration protocols and OEM data

- Submitting calibration records or certifications

No internet? A wireless hotspot or dedicated router is a good solution.

Ready to Get Started? Let Defy Diagnostics Help

Launching an ADAS calibration service is a big step—but it’s also a smart one. With proper planning and support, you can tap into a growing market while helping improve road safety.

Not sure where to begin? We’re here to help you every step of the way.

Contact us today to learn how to integrate ADAS calibration into your business with confidence.