Here’s What Code 3712 Means — and How to Fix It Fast

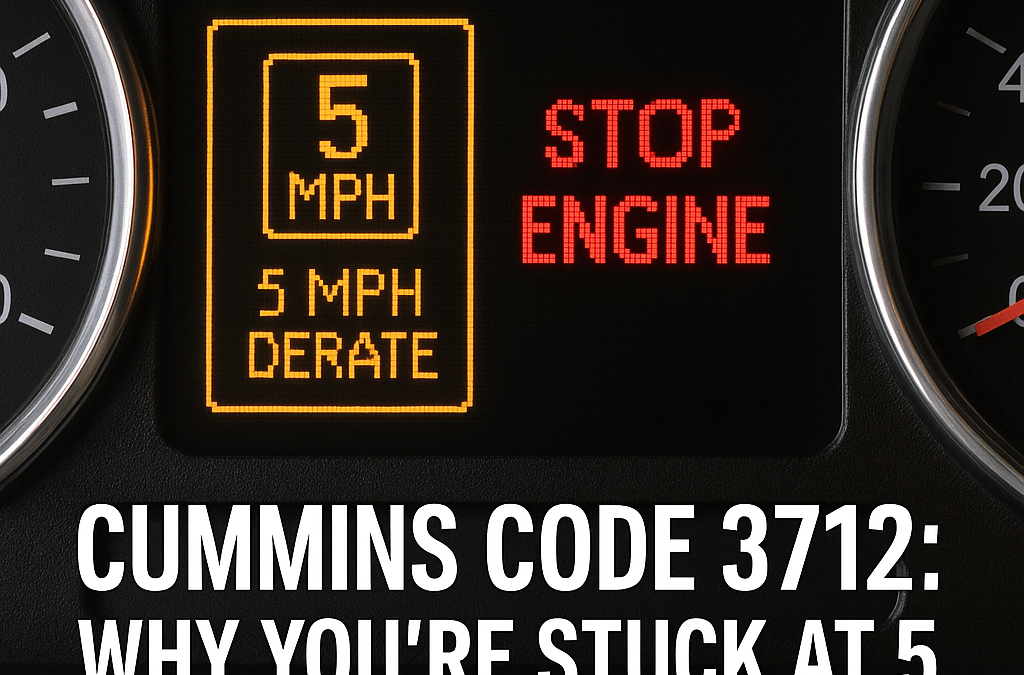

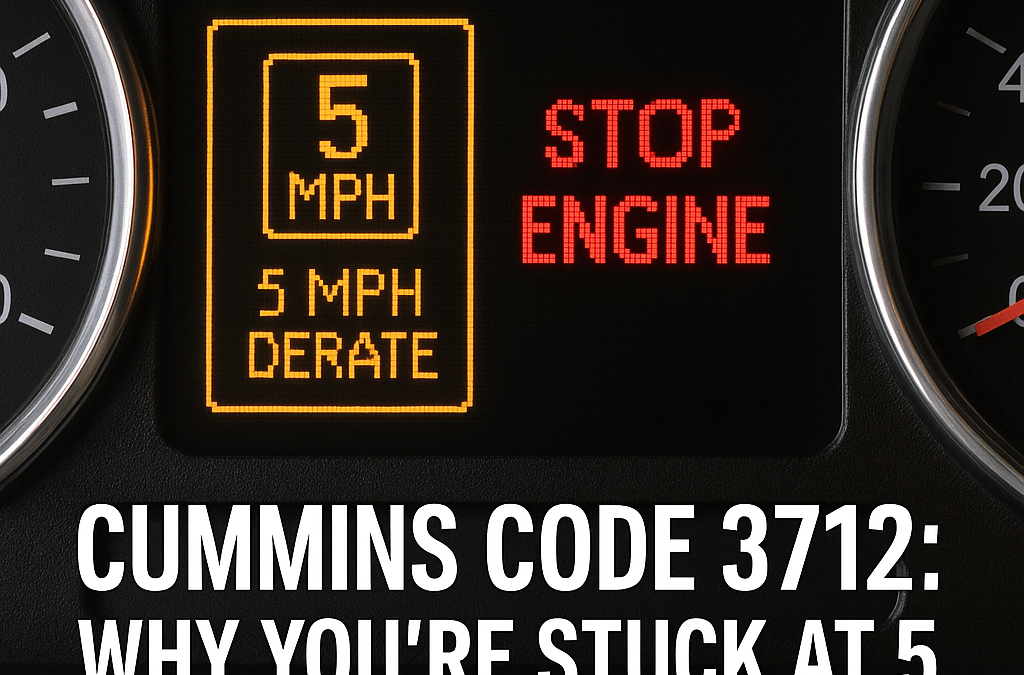

If you’ve ever had a Freightliner Cascadia, Kenworth T680, or Peterbilt 579 crawl into the shop stuck at 5 mph, chances are you’ve seen Cummins Fault Code 3712 staring you in the face. This one isn’t just a random check engine light — it’s an SCR inducement event tied to SPN 5246 FMI 0, and it means the system has had enough. Once this hits, you’re dealing with an emissions-related shutdown designed to force immediate repair.

Whether it’s an ISX15 in a long-haul tractor, a B6.7 in a Blue Bird Vision bus, or a QSX15 in a CAT 390 excavator, this fault code carries the same message: Your aftertreatment system is in critical condition — fix it now, or you’re parked.

Let’s break down what causes it, how to troubleshoot it properly, and why having the right diagnostic gear — like TEXA’s Axone Voice, Multihub 2, or the remote-capable TEXA eTRUCK — can make all the difference when time is money.

What Is Cummins Fault Code 3712?

This fault appears as SPN 5246 FMI 0, officially labeled “Aftertreatment SCR Operator Inducement – Most Severe Level.” It’s not a standalone fault — it’s triggered by other active, critical SCR-related codes. Think of it as the system’s way of saying: you’ve had your warnings, now you’re getting derated.

Which Engines and Vehicles Are Affected?

This fault code impacts a wide range of Cummins engines, including:

- ISX15 / X15 – Freightliner Cascadia, Kenworth T880, Peterbilt 389

- B6.7 / ISB – Blue Bird Vision, Thomas Built buses, delivery vehicles

- ISL9 / ISC8.3 – International MV Series, vocational trucks

- QSX15 – Off-highway equipment like excavators, generators, mining rigs

What Triggers Fault Code 3712?

While the root cause varies, here are the most common culprits:

- Malfunctioning inlet or outlet NOx sensors (especially if they can’t reach operating temp)

- DEF dosing valve or pump failure due to contamination or crystal buildup

- SCR catalyst degradation from long-term exposure or fluid contamination

- Poor DEF quality (outside 31–34% range) or freezing/crystallization issues

- Wiring or ECM calibration issues impacting communication with aftertreatment system

Field Diagnosis: How the Pros Approach It

Step one: confirm that 3712 is paired with one or more actionable SCR-related codes. Then follow this basic workflow using professional-grade diagnostics:

- Scan with TEXA Axone Voice + Multihub 2 — pull active codes, view live data, and confirm calibration

- Inspect NOx sensor temps — 250°F+ for inlet, 450°F+ for outlet

- Visually inspect DEF lines for leaks, crystal deposits, and pressure issues

- Run dosing valve and SCR conversion efficiency tests using TEXA IDC6 software

Need fast regen access and live fault monitoring without rolling a truck? TEXA’s eTRUCK lets you monitor, diagnose, and even perform remote regens — ideal for fleets with Cummins-powered assets on the road.

Repair Procedures and Best Practices

Once you’ve confirmed the cause, here’s what usually comes next:

- Replace faulty NOx sensors and verify calibration

- Service or replace DEF dosing unit and clean tank if needed

- Replace SCR catalyst if efficiency is below threshold

- Flush DEF system and update ECM calibration

Once repairs are complete, use TEXA tools to run SCR efficiency tests, confirm sensor readings, and ensure fault codes clear properly before release.

Preventive Maintenance to Avoid Code 3712

- Test DEF quality monthly and replace fluid regularly

- Keep up with SCR catalyst efficiency testing

- Inspect NOx sensors and wiring every 90 days

- Update ECM calibrations regularly (Cummins typically releases updates every 6–8 weeks)

Stay Ahead of the Next Breakdown

At Defy Diagnostics, we’re here to keep your fleet running and your downtime to a minimum.

Sign up for our free newsletter and get:

- Pro diagnostic tips like this one

- Exclusive offers on TEXA tools and accessories

- Updates on IDC6 software features and releases

- Field-tested repair strategies you can trust

Sign up now and keep your shop one step ahead.

Detect AC Leaks with Confidence: Why the TEXA Forming Gas Kit Belongs in Your Shop

When it comes to A/C system diagnostics, guesswork is not an option. Whether you’re servicing a vehicle after a collision repair or troubleshooting a drop in cooling performance, identifying leaks quickly and precisely is critical — both for customer satisfaction and your bottom line.

That’s where the TEXA Forming Gas Kit with H₂ Detect comes in.

Tackle Micro Leaks Other Tools Miss

Traditional methods like nitrogen pressure testing or UV dye can leave you with more questions than answers:

- Nitrogen alone may show a pressure drop — but not the leak location.

- UV dye requires time, extra flushing, and often doesn’t pinpoint small or fast-dissipating leaks.

With TEXA’s Forming Gas Kit, you inject a 95% nitrogen / 5% hydrogen gas mixture into the system. Then, using the H₂ Detect sniffer, you can zero in on even the tiniest hydrogen molecule escaping — with visual and audible alerts that guide you directly to the leak source.

Hydrogen is the lightest, smallest molecule — making it ideal for tracking micro leaks in systems using R134a, R1234yf, or R744 (CO₂).

Built for Collision Repair & High-Precision A/C Service

If you’re recharging A/C systems without leak verification, you’re playing a risky game. Collision repairs often disrupt seals or lines — and the last thing your shop needs is a comeback. TEXA’s forming gas method:

- Meets Daimler AG requirements

- Is non-polluting and safe to use

- Works across multiple refrigerant types

- Detects even hard-to-find slow leaks before the system is recharged

What’s in the Kit?

Forming Gas Cart TTF 700

- Compatible with R134a, R1234yf, R744

- Max pressure: 100 bar

- Service hoses for all refrigerants

- Safety valve, pressure reducer, manometer

- Secure tank storage (tank not included)

Forming Gas Case

- Adapters, reducer, evacuation valve

- Teflon seals

- Connection kit for Konfort A/C machines

H₂ Detect Sniffer

- Measures hydrogen from 0 to 2000 ppm

- 14-second response time

- Visual and acoustic feedback

- 6-hour battery life

- Flexible probe for hard-to-reach areas

Who’s It For?

Whether you’re a:

- Collision center needing OEM-approved diagnostics

- Independent repair shop handling A/C complaints

- Dealer staying ahead of new refrigerant standards

- Mobile technician chasing down tough leaks

The TEXA Forming Gas Kit gives you the confidence to diagnose accurately — and avoid repeat repairs.

Need Help Getting Started?

Our team is here to help you integrate leak detection into your A/C service process. Need help pairing the kit with your Konfort 760 Touch or 780 Touch? Just ask.

📞 Talk to a Pro at Defy Diagnostics today.

Introduction

Are you tired of juggling multiple scan tools that only do half the job? Or worse—paying steep dealer prices just to reset a warning light?

From diesel fleets to sport bikes, marine engines to modern cars, today’s vehicles demand smart, flexible diagnostics. And if you’re a shop owner, fleet tech, or mobile mechanic, using outdated or brand-specific tools can cost you time, money, and clients.

This all-in-one mega-guide will walk you through TEXA’s diagnostic ecosystem—why it’s trusted worldwide, how to choose the right platform for your industry, and what tools give you the best return on investment.

We’ll break it down by sector—heavy-duty, automotive, marine, and Powersports—so you can skip straight to what matters most. You’ll get real-world recommendations, FAQs, and internal links to explore each product in depth.

🔧 Why TEXA? A Diagnostic Powerhouse Built for Technicians

TEXA diagnostic tools are built by engineers who actually listen to technicians. Their IDC6 software isn’t just user-friendly—it’s technician-smart, covering more makes and systems across industries than almost any competitor.

Over 100,000 workshops in 130+ countries use TEXA with 15+ years of diagnostic innovation.

Real-World Story: A shop in Georgia upgraded to a TEXA Axone Voice and cut vehicle downtime by 43% in the first quarter—just by gaining instant access to deeper, multi-brand diagnostics.

Pro Tip: If you service a mix of vehicles, TEXA’s cross-platform licensing means you can handle more jobs with one investment.

🚛 Heavy-Duty Diagnostics – Built for Fleets, Mobile Techs & Diesel Shops

Whether you’re diagnosing a Cummins ISX, resetting an SCR on a Volvo, or calibrating a Freightliner’s ADAS system, TEXA’s truck kits deliver OEM-level access without OEM headaches.

- Choose your platform: Axone Voice, Axone Plus, or PC-based

- Pair with Navigator TXT Multihub

- Install IDC6 Truck software

- Begin diagnostics across Freightliner, Kenworth, Mack, International, and more

Avoid This: Don’t expect regen features from basic readers—only pro tools offer full bi-directional support.

→ Deluxe Fleet Diagnostic Package

🚗 Automotive Diagnostics – Smarter Scans for Modern Cars

With deep European & Asian brand coverage, TEXA’s IDC6 Car software enables ADAS calibration, bi-directional testing, resets, and programming.

Recommended Kits:

- Axone Plus + Navigator Multihub

- Axone Voice

Case Study: A garage in NC eliminated 90% of Audi/BMW sublets with TEXA.

Tool Tip: Add RCCS3 Evo for in-house ADAS calibration.

→ RCCS3 ADAS Calibration System

🛥️ Marine Diagnostics – Plug into Outboards, Inboards & Jet Skis

TEXA’s marine software works with Mercury, Yamaha, Suzuki, Volvo Penta & more. Diagnose trim, ignition, fuel systems—on water or off.

- Axone Nemo Light or Axone Plus

- Marine software license

- OEM-specific cable kits

Supports Jet Skis (Sea-Doo, Yamaha, Kawasaki) and older marine engines.

→ TEXA Marine Kits

🏍️ Motorcycle & Powersports Diagnostics – From Dirt to Drag

TEXA covers Harley, Honda, Ducati, Polaris, Yamaha, KTM, BRP, ATVs, UTVs, and more.

Top Picks:

- Axone Light Bike Kit w/ Cables

- Axone Nemo Light

- Axone Voice Bike Kit

→ TEXA Bike Diagnostic Kits

📌 Key Takeaways

- ✅ TEXA spans trucks, cars, boats & bikes

- ✅ IDC6 gives you OEM-level access

- ✅ Smart bundles = less dealership reliance

- ✅ Start with your needs, not just price

Conclusion

If you’re tired of outgrowing scan tools or being tied to dealerships, TEXA’s ecosystem is the upgrade your shop needs. Diagnose more. Downtime less.

Next Step: Browse the category that fits you or Talk to a Pro.

Question: Which vehicles do you service most—and what’s holding you back from upgrading diagnostics?

🔗 Explore More

Newsletter CTA: Join our free newsletter