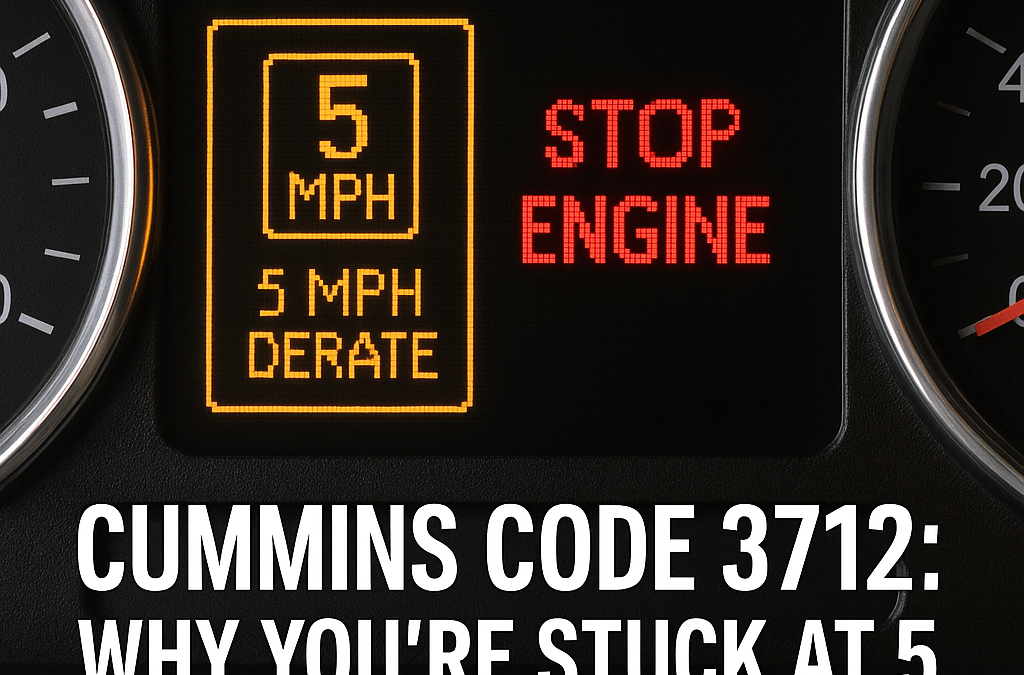

5 MPH Derate?

Here’s What Code 3712 Means — and How to Fix It Fast

If you’ve ever had a Freightliner Cascadia, Kenworth T680, or Peterbilt 579 crawl into the shop stuck at 5 mph, chances are you’ve seen Cummins Fault Code 3712 staring you in the face. This one isn’t just a random check engine light — it’s an SCR inducement event tied to SPN 5246 FMI 0, and it means the system has had enough. Once this hits, you’re dealing with an emissions-related shutdown designed to force immediate repair.

Whether it’s an ISX15 in a long-haul tractor, a B6.7 in a Blue Bird Vision bus, or a QSX15 in a CAT 390 excavator, this fault code carries the same message: Your aftertreatment system is in critical condition — fix it now, or you’re parked.

Let’s break down what causes it, how to troubleshoot it properly, and why having the right diagnostic gear — like TEXA’s Axone Voice, Multihub 2, or the remote-capable TEXA eTRUCK — can make all the difference when time is money.

What Is Cummins Fault Code 3712?

This fault appears as SPN 5246 FMI 0, officially labeled “Aftertreatment SCR Operator Inducement – Most Severe Level.” It’s not a standalone fault — it’s triggered by other active, critical SCR-related codes. Think of it as the system’s way of saying: you’ve had your warnings, now you’re getting derated.

Which Engines and Vehicles Are Affected?

This fault code impacts a wide range of Cummins engines, including:

- ISX15 / X15 – Freightliner Cascadia, Kenworth T880, Peterbilt 389

- B6.7 / ISB – Blue Bird Vision, Thomas Built buses, delivery vehicles

- ISL9 / ISC8.3 – International MV Series, vocational trucks

- QSX15 – Off-highway equipment like excavators, generators, mining rigs

What Triggers Fault Code 3712?

While the root cause varies, here are the most common culprits:

- Malfunctioning inlet or outlet NOx sensors (especially if they can’t reach operating temp)

- DEF dosing valve or pump failure due to contamination or crystal buildup

- SCR catalyst degradation from long-term exposure or fluid contamination

- Poor DEF quality (outside 31–34% range) or freezing/crystallization issues

- Wiring or ECM calibration issues impacting communication with aftertreatment system

Field Diagnosis: How the Pros Approach It

Step one: confirm that 3712 is paired with one or more actionable SCR-related codes. Then follow this basic workflow using professional-grade diagnostics:

- Scan with TEXA Axone Voice + Multihub 2 — pull active codes, view live data, and confirm calibration

- Inspect NOx sensor temps — 250°F+ for inlet, 450°F+ for outlet

- Visually inspect DEF lines for leaks, crystal deposits, and pressure issues

- Run dosing valve and SCR conversion efficiency tests using TEXA IDC6 software

Need fast regen access and live fault monitoring without rolling a truck? TEXA’s eTRUCK lets you monitor, diagnose, and even perform remote regens — ideal for fleets with Cummins-powered assets on the road.

Repair Procedures and Best Practices

Once you’ve confirmed the cause, here’s what usually comes next:

- Replace faulty NOx sensors and verify calibration

- Service or replace DEF dosing unit and clean tank if needed

- Replace SCR catalyst if efficiency is below threshold

- Flush DEF system and update ECM calibration

Once repairs are complete, use TEXA tools to run SCR efficiency tests, confirm sensor readings, and ensure fault codes clear properly before release.

Preventive Maintenance to Avoid Code 3712

- Test DEF quality monthly and replace fluid regularly

- Keep up with SCR catalyst efficiency testing

- Inspect NOx sensors and wiring every 90 days

- Update ECM calibrations regularly (Cummins typically releases updates every 6–8 weeks)

Stay Ahead of the Next Breakdown

At Defy Diagnostics, we’re here to keep your fleet running and your downtime to a minimum.

Sign up for our free newsletter and get:

- Pro diagnostic tips like this one

- Exclusive offers on TEXA tools and accessories

- Updates on IDC6 software features and releases

- Field-tested repair strategies you can trust

Sign up now and keep your shop one step ahead.